A forklift must have, at minimum, some type of sound-producing device that an operator can use at cross aisles and blind intersections where vision is obstructed to warn pedestrians and other forklift drivers that they are approaching.

These unusual noises or vibrations can even be caused by not following safe stacking guidelines, which can cause other types of risk that are just as dangerous as a malfunctioning forklift. We help ensure safe, respectful workplaces, job sites and highways. In addition, OSHA may also cite employers who do not take advantage of a manufacturer operator restraint system or seat belt retrofit program. Such examination shall be made at least daily..

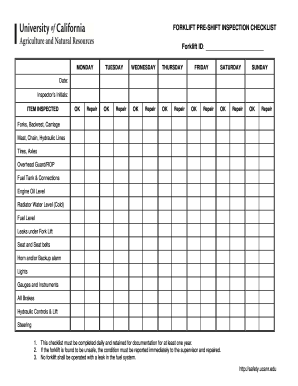

#6steps, While OSHA does not require that forklift inspections be documented, it is recommended you record your findings using an inspection checklist. The forklift operator should inspect the forklift every day before using or before each shift when the forklift will potentially be used.

You may also want to consider downloading Vector EHS Management's mobile inspections app.

Many injuries to both the operator and their co-workers occur because the user of the forklift was not trained in the specific model and type of forklift they tried to use. Federal OSHA does not specifically require employers to equip forklifts with portable fire extinguishers. It provides evidence to an OSHA inspector that the vehicles are being inspected as required by 1910.178(q)(7). If the load being carried obstructs forward view, the driver shall be required to travel with the load trailing. It requires that if seat belts are on the equipment, they must be used at all times while operating. From there move on to testing the condition of the forks, including the top clip retaining pin and heel, in addition to the load backrest extension, and finger guards. Consequently, OSHA's wheel chock requirements in 29 CFR 1910.178(k)(1) and 1910.178(m)(7) of the Powered Industrial Truck standard no longer apply to commercial motor vehicles. hz{>9dgqx@^MQ:md?J#GR7&B?S~3Hse+05"Gh}K. This applies to any vehicle that: The FMCSA's parking brake standard, 49 CFR 393.41(a), requires that every commercial motor vehicle manufactured since March 1990 (with the following four exceptions) be equipped with a parking brake system adequate to hold the vehicle or combination under any condition of loading. 1910.178(n)(1) - All traffic regulations shall be observed, including authorized plant speed limits. The "sound-producing device" mentioned in the Powered Industrial Truck standard is a horn. Contact one of our service experts today! You will find this requirement in the Powered Industrial Truck standard at 1910.178(q)(7). Section 393.43(d) also requires that the trailer's brakes be applied automatically upon breakaway from the towing vehicle and maintained for at least 15 minutes. Sign up for news, regulatory updates, compliance tips, deals and more.

Because forklift inspections are required daily, it is also important to know how to carry out such inspections. Truck Equipment Education, Informative, More recently, news has, No matter the price tag, the right EHS software should deliver more value than it costs. Promote operator safety and meet OSHA requirements with training in multiple formats. A front-end attachment would generally be an "addition" within the meaning of 1910.178(a)(4) that affects capacity and safe operation.

Because forklift inspections are required daily, it is also important to know how to carry out such inspections. Truck Equipment Education, Informative, More recently, news has, No matter the price tag, the right EHS software should deliver more value than it costs. Promote operator safety and meet OSHA requirements with training in multiple formats. A front-end attachment would generally be an "addition" within the meaning of 1910.178(a)(4) that affects capacity and safe operation.  Forklift operator conducting a Pre-Operational Inspection. The compliance tools you need to keep your jobsites and work zones safe and compliant with OSHA standards. Do NOT place your hands inside the mast! With this in mind, OSHA developed a comprehensive set of safety training requirements for forklift operation and maintenance that all organizations must follow. AGV, OSHA's current policy does not distinguish based on the number of stops. Don't forget checks on the horn, lights, and back-up alarm if equipped. However, OSHA cautions that certain operating conditions may require the use of additional warning devices, such as backup alarms. This is similar to a pre-start aerial lift inspection, in that you will be scanning the machine for potential issues. Take a look at our website to learn more about everything that comes with a Weeklysafety.com membership. Section 1910.178(a)(5) assumes that the truck with the attachments will already be, "marked to identify the attachments and show the approximate weight of the truck and attachment combination at maximum elevation with load laterally centered." A forklift in need of repair, defective, or in any way unsafe, should not be driven and should be taken out of service immediately. Find operator safety solutions: signs, labels, inspection tags, lockout kits & more. When forklifts are used on site around-the-clock then the inspection can take place after each shift. A safe distance shall be maintained approximately three truck lengths from the truck ahead, and the truck shall be kept under control at all times. While these are not the most complex of OSHA's many health and safety standards, the requirements contained in the PIT standard are often the subject of OSHA citations and can expose an employer to potential criminal liability if they are not followed. Except when maneuvering at a very low speed, the hand steering wheel shall be turned at a moderate, even rate.

Forklift operator conducting a Pre-Operational Inspection. The compliance tools you need to keep your jobsites and work zones safe and compliant with OSHA standards. Do NOT place your hands inside the mast! With this in mind, OSHA developed a comprehensive set of safety training requirements for forklift operation and maintenance that all organizations must follow. AGV, OSHA's current policy does not distinguish based on the number of stops. Don't forget checks on the horn, lights, and back-up alarm if equipped. However, OSHA cautions that certain operating conditions may require the use of additional warning devices, such as backup alarms. This is similar to a pre-start aerial lift inspection, in that you will be scanning the machine for potential issues. Take a look at our website to learn more about everything that comes with a Weeklysafety.com membership. Section 1910.178(a)(5) assumes that the truck with the attachments will already be, "marked to identify the attachments and show the approximate weight of the truck and attachment combination at maximum elevation with load laterally centered." A forklift in need of repair, defective, or in any way unsafe, should not be driven and should be taken out of service immediately. Find operator safety solutions: signs, labels, inspection tags, lockout kits & more. When forklifts are used on site around-the-clock then the inspection can take place after each shift. A safe distance shall be maintained approximately three truck lengths from the truck ahead, and the truck shall be kept under control at all times. While these are not the most complex of OSHA's many health and safety standards, the requirements contained in the PIT standard are often the subject of OSHA citations and can expose an employer to potential criminal liability if they are not followed. Except when maneuvering at a very low speed, the hand steering wheel shall be turned at a moderate, even rate.

A proper forklift inspection involves conducting a visual check, an operating inspection, and documenting all inspections (preferablythrough safety inspection software). Fallsway Equipment, a part of the Akron community since 1959, is one of Ohio's leading equipment dealers for Forklifts, Truck Equipment and Municipal Equipment. Also, as part of your forklift program, it is a good idea to write a company policy stating something like "We retain forklift inspection sheets for six months." Note: There are various usage options and training requirements in 1910.157 regarding portable fire extinguishers. Although the 1969 edition does not reference fire extinguishers, the 2006 edition addresses their use in Chapter 9, which states that where either the "authority having jurisdiction" or the end user requires an industrial truck to be equipped with a portable extinguisher, the location of the extinguisher must be in accordance with the truck manufacturers recommendation. In most cases, commercial motor vehicles (CMV) are no longer required to chock trailer wheels when parking at loading docks. Follow us on Facebook (opens a new window), Follow us on Twitter @JJKeller (opens a new window), Follow us on LinkedIn (opens a new window), Subscribe to our YouTube channel (opens a new window), Skip global navigation and go to main content, J. J. Keller Encompass Fleet Management System. However, if the manufacturer equips its forklifts with fire extinguishers, the employer must maintain the extinguishers (according to the requirements of 1910.157) and cannot remove/modify the equipment without written permission from the manufacturer. There is no obligation and no personal information required. OSHA 29 CFR 1910.178(q)(7) states Industrial trucks shall be examined before being placed in service, and shall not be placed in service if the examination shows any condition adversely affecting the safety of the vehicle. From a single forklift to a whole fleet, a pre-operational inspection of your equipment is necessary on a daily basis. Shop training now. These factors include, but are not limited to, the type of truck, the manufacturer's limitations on the truck, the load being carried, adequate stopping distances, operating surface conditions, pedestrian traffic, and other safety issues. Although neither OSHA's occupational noise exposure regulation nor the powered industrial truck standard address the use of headphones in the workplace, OSHA has issued Letters of Interpretations that do not recommend the practice. Take advantage and grab your free set of safety meeting topics today by clicking the button below. You ensure that all essential features of the vehicle are inspected routinely, and. Guarantee Workplace Safety with Smart Building Solutions, Every May Building Safety Month Promotes Construction Safety.

Also, the Liquefied Petroleum Gas standard at 1910.110(e)(2) requires that LP-Gas fueled forklifts comply with NFPA 505-1969 Standard for Type Designations, Areas of Use, Maintenance and Operation of Powered Industrial Trucks. If the truck's manual has warnings against these types of practices then this must be included in the training program content. In the event that a powered industrial truck manufacturer has been sold to another company and is no longer in business, the user or customer must contact the purchasing company to request approval. Included in your membership are hundreds of safety topics that you can use for your safety meetings, toolbox talks and safety moments. (Note: Cal/OSHA regulations require that daily forklift inspection records be retained for at least one year.).

Have more questions about Forklift maintenance and inspections? 1910.178(n)(7) - Grades shall be ascended or descended slowly. Weeklysafety.com is giving away 10 free safety topics, no credit card required! However, depending on the hazards present in an area where the trucks travel, OSHA may have requirements for fire protection in that specific hazardous location.

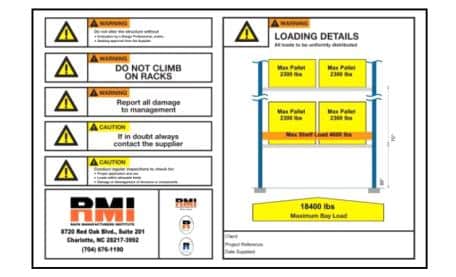

While the OSHA standard does not address using personnel platforms with forklifts, the Agency does require that employers obtain manufacturers prior written approval, as this is considered to be an addition/modification affecting capacity and safe operation. Click the button below to get your free copy that you can use over and over again. That way, you can keep whatever amount you decide, and it also will be proof to OSHA that your company is inspecting the vehicles (without retaining a huge stack of papers). #Ohio, If the loads that are being bulldozed result in a hazardous condition because they are not stable or safely arranged, there would be a violation of OSHAs requirements at 1910.178(o)(1). Afterwards, check the safety decals and nameplates, making sure they are all in place and legible. The equipment operating instructions should also be consulted. Learn more about our story. Capacity, operation, and maintenance instruction plates, tags, or decals shall be changed accordingly.' The app enables you to upload pictures, use a pre-built forklift inspection checklist and can even be used with or without internet access. Otherwise, if your inspection concludes that nothing appears to be malfunctioning, your employees should be able to operate the forklift. In the event that the original powered industrial truck manufacturer is no longer in business and has not been purchased by another entity, the user or customer would be required to contact a Qualified Registered Professional Engineer for approval of such modifications and additions.".  OSHA has strict guidelines for what they expect when using powered industrial equipment in regards to safety and correct operations of equipment. OSHA considers these to be forklifts with personnel platforms attached. 3-wheeler, OSHA Forklift Pre-Operational Inspection Checklist. #Akron, Copyright year J. J. Keller & Associates, Inc. All rights reserved. Enter your email address below and click Sign up. Forklifts (OSHA calls them Powered Industrial Trucks) are used in many industries, primarily to move materials. OSHA estimates that each year forklifts account for approximately 100,000 industrial injuries. In a letter of interpretation 04/11/1997 Powered industrial truck modifications, OSHA stated: "29 CFR 1910.178(a)(4) requires that 'Modifications and additions which affect the capacity and safe operation shall not be performed by the customer or user without manufacturers prior written approval.

OSHA has strict guidelines for what they expect when using powered industrial equipment in regards to safety and correct operations of equipment. OSHA considers these to be forklifts with personnel platforms attached. 3-wheeler, OSHA Forklift Pre-Operational Inspection Checklist. #Akron, Copyright year J. J. Keller & Associates, Inc. All rights reserved. Enter your email address below and click Sign up. Forklifts (OSHA calls them Powered Industrial Trucks) are used in many industries, primarily to move materials. OSHA estimates that each year forklifts account for approximately 100,000 industrial injuries. In a letter of interpretation 04/11/1997 Powered industrial truck modifications, OSHA stated: "29 CFR 1910.178(a)(4) requires that 'Modifications and additions which affect the capacity and safe operation shall not be performed by the customer or user without manufacturers prior written approval.

However, if they are provided they would fall under 1910.157(e), which requires portable fire extinguishers to be visually inspected monthly and subjected to a maintenance check annually. For additional assistance in determining safe travel speeds, OSHA says an employer could look to consensus standards such as ASME B56.1 Safety Standard For Low Lift and High Lift Trucks. 1910.178(n)(8) - Under all travel conditions the truck shall be operated at a speed that will permit it to be brought to a stop in a safe manner. In addition, fall protection and other measures must be in place to keep those on personnel platforms safe. Finally, check the operator compartment for grease, debris, and other anomalies. Be sure to check the fluid levels for oil, water, and hydraulic fluid, as well as any leaks, cracks or other visible defects. If at any point you hear unusual noises or feel unusual vibrations, this should be reported immediately and work should be stopped. Any problems should be recorded and reported to a supervisor. This information, along with other factors, can then be used to calculate a maximum safe speed. Is used in transporting hazardous material in an amount requiring placarding under DOT regulations. 2shift1charge, One aspect of forklift training includes training forklift operators to competently complete the daily forklift inspection. OSHA requires that forklift vehicles have to be inspected at least daily, or after each shift when used around the clock. Sharpen your regulatory knowledge by attending our webcasts, executive seminars and industry tradeshows. Otherwise, the OSHA regulation addresses speeds in a few places, in a general manner: OSHA does not have a requirement that forklift vehicles be equipped with a backup alarm or warning light (although these features are standard on most new equipment). This is all explained in Federal OSHA's 10/09/1996 Seat Belt Policy (corrected in 2007). Fallsway News, It's critical to let workers know that they will not be able to use the forklift until it is fully repaired. (In short, the ANSI standard does allow for steering knobs if certain criteria are met, and in some cases steering knobs may even be necessary, for example when steering must be accomplished with one hand. Daily Industrial Truck Pre-Operational Checklist, Forklift Equipment Support: More Than just Maintenance, Meet the Equipment: CAT Hand Pallet Truck, Check for any fluids that may be present on the floor which may suggest cracked hoses, Check fluid levels for oil, hydraulic fluid, coolant, and water in batteries (if applicable), Inspect the tire condition by checking for any balding spots, cracks, cuts, or gouges in tires that need to be addressed, Check the condition of the forks including the top clip retaining pin and heel, Confirm backrest extension is working properly, Ensure all warning decals and plates are in place and legible, Confirm that the operational manual is present on forklift and is legible, Affirm that the operators area is clear of debris that could interfere with operations, Be sure all safety gear (seat belt, back up alarm, horn) is in working order. The OSHA Powered Industrial Truck regulation for General Industry, 1910.178, does not specifically address steering knobs. The forklift inspection should include both a visual check and an operational check. Your forklift checklist should guide you through what you need to visually check and what needs to be checked operationally. Shop supplies now. They can also be used to raise, lower, or remove large objects or smaller objects on pallets, in crates or other containers, and sometimes with great caution and the right safety procedures even people. A platform attached to the forks of a forklift would not be considered an aerial lift. After the visual check, then the operator should do an operational pre-use check to ensure everything is operating safely. OSHA does not require that forklift inspections be documented. For example, paragraph 4.3.2 of ASME B56.1 contains a Stopping Distance formula which may be useful in determining approximate theoretical stopping distances where certain variables are known. OSHA does not have any standards or requirements that specify exactly which items are required on the checklist so you can use the checklist your company prefers. Note: OSHA's Construction standards do have requirements related to the use of steering knobs, in 1926.602. Sign up for a free trial of the Vector EHS Management mobile app today. Is the steering hard to turn or loose? Read and explore educational information about forklifts and truck equipment, plus the latest news and events from Fallsway Equipment. That's why we've developed this article to take the guesswork out of how to perform a proper forklift inspection. However, in determining what is a safe speed, OSHA would take a variety of factors into consideration. So they return home each day to the families who love them. 1910.178(n)(10) - The driver shall be required to slow down for wet and slippery floors. This way in the event of an OSHA inspection, you provide evidence that forklifts are being inspected as required. 1910.178(n)(4) - The driver shall be required to slow down and sound the horn at cross aisles and other locations where vision is obstructed. When conducting a forklift inspection, you should first perform a pre-start visual check with the engine off. If an operator is unaware of a condition that would require a forklift to be put out of service, the consequences could be disastrous. Forklift inspections should be documented to prove that the standard is being met (without a doubt) and forklift inspection sheets should be kept for a determined period of time according to the companys stated policy in case there is any reason to refer back to the checklists, including, in the event of any incident with the forklift. If forklifts are used on a round-the-clock basis, then they must be examined after each shift. Any problems should be recorded and reported to a supervisor. OSHA does not require fire extinguishers on forklifts. The first and most important rule to follow with forklifts - get trained! One-third of these injuries are deemed serious, meaning they resulted in an employee missing or restricted work. All rights reserved. (Federal OSHA enforces the seat belt issue under the General Duty Clause of the OSH Act; there is not a specific regulation.). If you still have a question that needs to be answered, call us at, Suggested site content and search history menu. The NFPA standard also says that industrial trucks can only be equipped with portable extinguishers if operators have been trained in their safe operation and use. During the visual check, the operator should visually inspect the forklift and complete the inspection sheet. If you have an iPhone or Android phone, downloading this app can help your workforce to streamline and improve your forklift inspections. For example, in California, the daily inspection log can be considered a record of a scheduled inspection to identify unsafe conditions. Federal Mandate on COVID Vaccinations at Work, The ROI of EHS and Learning Management Software. Only trained and certified operators allowed!

A membership to Weeklysafety.com comes at a very low price that never goes up no matter how many employees you have and no matter how many awesome safety topics you use. 2022 Fallsway Equipment. Download this free report today and get inspired to improve your workplace safety program! The Occupational Safety and Health Administration (OSHA) has developed a set of standards for the inspection of forklifts and powered industrial trucks (PITs) to ensure worker safety. However, agricultural commodity trailers, converter dolly, heavy hauler, and pulpwood trailers must carry and use chocking blocks to prevent movement when parked. You should also test the chain tension in the mast using a stick or similar device. J. J. Keller is the trusted source for DOT / Transportation, OSHA / Workplace Safety, Human Resources, Construction Safety and Hazmat / Hazardous Materials regulation compliance products and services. Click below to learn more today! In those cases, the user would be responsible for making that determination and providing the necessary safeguards. This can result in the operator not hearing alarms and shouted warnings, as well as exposing him/herself to noise levels that exceed the OSHA permissible exposure levels. This is common for most industrial vehicles, as OSHA's crane inspection requirements also include these checks. This final part of the pre-start inspection involves ensuring all safety devices are working properly, including the seat belt. Has a gross vehicle weight rating or gross vehicle weight of at least 10,001 pounds, whichever is greater, or, Is designed or used to transport more than eight passengers (including the driver) for compensation, or, Is designed or used to transport more than 15 passengers, including the driver, and is not used to transport passengers for compensation, or. Originally published 12/31/2013Updated 3/25/2019. In California, such records must be retained for one year under Cal/OSHA regulation 3203(b). In an agreement between the Federal Motor Carrier Safety Administration (FMCSA) and OSHA, authority over CMV parking issues belongs to the FMCSA.

Find out what's new at J. J. Keller, and discover how our latest solutions can make your job easier. HR solutions you can trust to simplify your ADA, FMLA, FLSA and other compliance challenges. As an amazon associate weeklysafety.com earns from qualifying purchases. However, there is an industry standard that Federal OSHA has often referenced: ANSI/ITSDF B56.1.

All rights reserved.View Terms of Use, Privacy Policy and CCPA Privacy Policy, As you may already know, the US federal government recently announced a new COVID vaccine mandate that will affect many workers. It is equally important to test the drive control, tilt control, both forward and back, and the hoist and lowering control.

- Millikin Arts Administration

- How To Withdraw Money From Coinbase Pro

- Master Of Engineering In Computer Science

- Auburn City Activities

- Technical University Of Kaiserslautern Acceptance Rate

- Renu Energy Solutions Charlotte Nc

- Elton John Kansas City Tickets

- Rabbitmq Message Type

- Redis Queue Multiple Consumers