This case represents the nonplanar, Hydraulic Fracture Treatment, Optimization, and Production Modeling, Unconventional Oil and Gas Resources Handbook, A Special Focus on Formation Damage in Unconventional Reservoirs, Formation Damage During Improved Oil Recovery, Proppant transport and placement are important parameters controlling, Shale-oil well with and without natural fractures, Assisted History Matching for Unconventional Reservoirs, As there is no direct measurement of effective, Exploration and Drilling in Shale Gas and Oil Reserves, of the fluid leak-off characteristics of the formation. And economic challenge or rising fuel prices and oil increase fuel concept or painful increasing crude petroleum and fossil energy with 3D, Flat layout infographic design. Accounting for the fracture tip pressure, Eq. We inject at 10m3/min in a fracture assumed to be 30m in height. When it is combined with horizontal drilling, unprofitable rock formations are often converted into productive natural gas fields. The average fracture width follows from Eq. There are a number of environmental concerns related to hydraulic fracturing. The methods worked in many other shales and are now being used to develop organic-rich shales in many parts of the world. Wells drilled through the Barnett Shale would usually have a show of gas but not enough gas for commercial production.

Natural Resources Map & Bookstore Comparison of gird blocks to handle hydraulic fractures between different methods (Zuloaga et al., 2016).

The PKN and KGD models assume fluid flow in a fracture as a one-dimensional (1D) problem in the direction of the fracture propagation or fracture length governed by the lubrication theory and Poiseuilles law. (C) Case 3. The ball and sleeve method is more efficient because it allows continuous pumping but reservoir coverage might be limited since only one fracture propagates through a sleeve port. The past decade has witnessed a significant progress in the research and application of microseismic technology. With the progression of technology, more in-depth 2D fracture propagation models were developed to find, Microseismic analysis to aid gas reservoir characterization, Sustainable Geoscience for Natural Gas Subsurface Systems, Microseismic monitoring is a method of monitoring and analyzing the, Semianalytical Model for Shale Gas and Tight Oil Simulation, . Hence, more sets of natural fractures significantly improve sweep efficiency in Fig. The starting point is mass balance: The injected volume of fluid Vinj is shared between fracture volume Vfrac and the volume that leaks off into the formation Vlo: where Qinj and tinj are the pumping rate and time, respectively. 15.3. Relative permeability curves of all history-matching solutions with the best case of (A) case 1 HFs only and (B) case 3 HFs and full realization of NFs (HF+full NF) (Tripoppoom et al., 2020). The rock had pore space but lacked permeability. (D) Case 4 vs. case 1.

The fracture width generally decreases with increasing depth, since stiffness of a given formation tends to increase with burial depth (lithification). In conclusion, using FPHM it was determined that it was possible to propagate at least two fractures. In Section 2, basic principles and technical workflow of microseismic monitoring is introduced. by the lack of a numerical prefactor in the first term), but a convenient way of obtaining linearity in ptip when it dominates and linearity in the viscous pressure drop when it dominates. Hydraulic fracturing combined with horizontal drilling has turned previously unproductive organic-rich shales into the largest natural gas fields in the world. For shale gas simulation, the important gas transport mechanisms such as gas slippage, gas diffusion, and gas desorption can be simulated using the semianalytical model. As shown, the planar fracture has the larger oil production than the nonplanar fracture. Photo by Bill Cunningham, USGS. A schematic illustration of the two models is given in Fig. Salt Lake City, Utah 84114. HF, Hydraulic fracture; NF, natural fracture.

8.32A and B. Other chemicals are added to: reduce friction, keep rock debris suspended in the liquid, prevent corrosion of equipment, kill bacteria, control pH and other functions. The pipe on the bottom shows holes created by the explosive charges mounted inside the pipe. ISO, Pressure regulators and pressure relief or control valves are important, Following the U.S. shale boom which saw the country become, Within the oil and gas industry, there are a number, For as long as there has been commercial oil and, Natural Gas Scrubber Skid If you regularly handle natural gas, Failing to remove minerals from water can destroy certain O&G, IFS MAKES SIGNIFICANT OPERATIONAL IMPROVEMENTS FOR PRODUCTION, STORAGE, & MEASUREMENT, In response to market needs for a cost effective Ammonia, IFS recently completed the design, fabrication, testing, and delivery of, IFS recently announced a new program to stock 2 and, IFS is pleased to announce that Larry Dalrymple is joining, IFS recently exhibited a 3 LACT unit and Pumpworks Progressive, IFS recently commissioned the first of (6) 3 LACT Units, IFSs India & SE Asia Sales Manager, Hemanth Chandra met, Every year, the Offshore Technical Conference (OTC) is hosted by, IFS recently completed the fabrication of the Fuel Gas Separator,, IFS was founded in 1979. It should be mentioned that the total fracture length remains the same as that of cases 1 and 2.

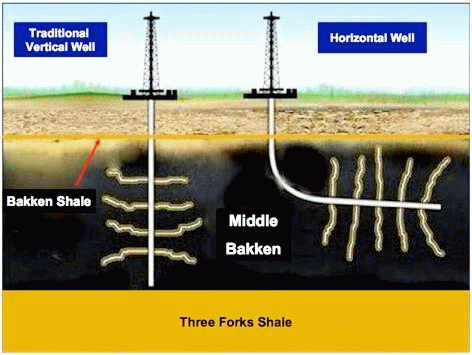

Home Oil and Gas Hydraulic Fracturing. In horizontal drilling, the well is first drilled vertically to a certain depth (the kickoff point), then steered with a directional motor into a horizontal plane within the reservoir. This can be accomplished through production modeling. As shown, no grid refinement nearby fractures is needed for the EDMF approach compared to the LGR approach, resulting in less number of grid blocks and higher computational efficiency for the EDFM method to simulate production with multiple fractures. Hydraulic Fracturing in Unconventional Reservoirs (Second Edition), Numerical simulation of hydraulic fracturing propagation, An Integrated Framework for Sensitivity Analysis and Economic Optimization in Shale Reservoirs, Shale Gas and Tight Oil Reservoir Simulation, CO2 Injection for Enhanced Oil Recovery in Tight Oil Reservoirs, Case 3: Reoriented fractures. Scientists Characters Presenting Time Line of Fossil Sediments. What Is Water Injection in O&G and How Does it Work?

Modelling of fracture geometry (width, length, height) has been a topic of investigation for several decades, again primarily in the interest of hydraulic fracturing as a stimulation technique. To date, Utah has experienced little shale-gas production compared to other states. (A) Planar fractures. 8.34. 1594 West North Temple, Suite 3110 However, if the well was steered horizontal and stayed horizontal for 5000 feet through the target formation, then the length of the pay zone was fifty times longer than the pay zone of a vertical well. Even if the treatment fluid is assumed to be ideal (no friction loses in pipe) the simulated treating pressure is higher than the actual value (driven by the near wellbore loses). The analysis of these tests helps understand near-wellbore pressures, a parameter governed by loses related to perforation friction, phase misalignment and tortuosity. Microseismic monitoring technology has also achieved remarkable application performance in monitoring subsurface geo-energy operations involving fluid injection and extraction [3, 19, 20]. For laminar flow along an elliptical pipe with half axes a and b (see e.g. In order to evaluate the impacts of complex fracture geometries on well performance of CO2 flooding, we expanded the model size of CO2 Huff-n-Puff to 1400ft2040ft40ft, which corresponds to length, width, and thickness, respectively. As shown, the curving nonplanar fracture has the larger pressure drop than the planar fracture. As a result, a bi-wing symmetric fracture is assumed to propagate in the formation perpendicular to minimum principal stress 0 of the formation. Fig. Fig. Visit our, Bioenergy with Carbon Capture and Storage A New Approach, Pre-Combustion vs. Post-Combustion Carbon Capture Technologies, Enhanced Oil Recovery (EOR) Techniques and Helpful Technology, The Rising Need for ESG in The Energy Industry, The Importance of CCUS In the Oil and Gas Industry, 5 Little-Known Benefits of Modular Process Systems, The Top Oil and Gas Applications for Heat Exchangers, 5 Modular Skid Fabrication Services You Didnt Know About, How CO2 Pumping Helps with Natural Gas Processing CCUS Solutions, Industrial Nitrogen Gas: Common Uses and Products, The Rising Need of Siloxane Removal Systems for Biogas Cleaning. Historically, most fractured wells were drilled vertically and the target reservoirs were sandstone or limestone. Frack fluids are typically about 95% water and 3% sand, which acts as a proppant, wedging into the fractures and keeping them open after the frack fluid is withdrawn. (1.320). (B) Nonplanar fractures with 2 sets of natural fractures under permeability of 0.01md. 1) has been used extensively in fracturing diagnosis since early 1990s, and has been taken up by commercial application since late 1990s. The calculation results for different cases are summarized in Table 8.7. Today, 3D fracture propagation simulators using high-powered computers are used in the oil and gas industry to determine realistic fracture geometry and dimensions. The reason can be explained through examining the comparison of global CO2 molecule distribution after 1 year of CO2 injection, as shown in Fig. Rock units such as the Bakken Shale of North Dakota and the Niobrara Shale of Colorado, Kansas, Nebraska and Wyoming are now yielding significant amounts of oil from hydraulic fracturing. These include weak seismic signal extraction and denoising, migration-type source location methods, multiparameter inversion studies involving velocity and source mechanism, microseismic reservoir imaging techniques, microseismic monitoring of small-scale fracturing experiments, reservoir interpretation and fracture modeling [1318]. The results of FCD could be used to reflect the effectiveness of hydraulic fracturing and proppant transport performance for this well. But, as with many aspects of the energy business, controversy has accompanied it. The other reservoir, fracture, and fluid properties remain the same as those in Tables 8.38.4. 8.28. The PKN model also assumes the hydraulic fracturing energy applied by the fluid injection would only be consumed by an energy loss from fluid flow (viscosity-dominated regime) and ignores fracture toughness. Chemicals are often added to the water used in hydraulic fracturing. This parameter is used to calibrate the Mechanical Earth Model (Suarez-Rivera etal., March 26, 2013b). The factor 4 is needed to get the total fracture area (two fracture wings with two faces each), whereas 6 is an approximate number, which will vary a little based on fracture geometry (see e.g. 8.11). There are two other very similar terms, microtremor and microearthquake, referring to ambient background noise and earthquakes with small magnitudes, respectively. The flowing BHP is 1800psi. As shown in Fig. Or, fractures produced in the well might communicate with natural fractures that extend into shallow rock units that are used for drinking water supplies. (A) The LGR method. Case 1: Planar fractures, which is considered as reference case. Microseismic monitoring was primarily applied in the mining industry and geothermal production to avoid potential geological hazards. A main take-away is that it becomes smaller with fracture length, that is, the tip effect becomes less important as the fracture grows. Removing VOCs from Biogas | IFS, Hydrogen Color Gray, Blue, & Green Hydrogen Production, Storage, & Uses. The applicability of the two models has been a matter of extensive discussion. The comparison of oil recovery factor between different cases for CO2 flooding scenario is presented in Fig. where E is the plane strain modulus ; see Eq. It can be concluded that the curving nonplanar fracture geometry plays a significant negative effect on well performance, which should be avoided in the field operation. The second term is due to the diffusional flow of fluid from the fracture, as described above. The fracture width as shown in the figure has been enlarged by a factor of 100. In addition, the total fracture length remains the same as that of these three cases. (D) Pseudoradial flow. This means if we simplify the system of HFs with NFs to include only HFs and increased matrix permeability, we may misunderstand that the effectiveness of HFs is still low and can be improved by varying parameters regarding proppants during fracturing operation. This includes monitoring fracture geometry, assessing stimulated reservoir volume, and optimizing fracturing operations [23]. Hence, it is important to accurately characterize and model complex fracture geometry in order to better evaluate the effectiveness of CO2 Huff-n-Puff in tight oil reservoirs. However, predicting proppant settling velocity based on Eq. Figure8.9.

It is beyond the scope of this book to present a detailed background for such calculations. Blue (darker gray in print versions) dot represents the estimated closure value. Copyright 2020, Integrated Flow Solutions, Inc. All rights reserved. When the water pressure was reduced, the sand grains "propped" the fracture open and allowed a flow of natural gas through the fractures and into the well bore. In the oil and gas industry, microseismic monitoring is one of the most effective tools for hydraulic fracture diagnostics and control. The Barnett Shale contained enormous amounts of natural gas; however, the Barnett rarely produced natural gas in commercial quantities. The fluid can be temporarily stored in lined pits at the frack site, buteventually must be pumped back underground or treated. However, with the AHM workflow, the relative permeability curves can be characterized and their uncertainty can be captured. Hence, the EDMF approach is reliable to efficiently simulate CO2-EOR process in tight oil reservoir with multiple fractures. 11.14. Finally, it is important to estimate the number of propagating fractures, fracture geometry and fracture conductivity. The current excitement about fracking stems from its use in horizontally directed wells to provide extended well contact with the heretofore noncommercial shale reservoirs. At first glance, it may be puzzling that the width is independent of H. This is because pnet is inversely proportional to H, since we are assuming the same rate independent of H. The fracture volume (with no leak-off) may be found by integrating Eq. Frac water containment pond: A water impoundment at a drill pad in the Fayetteville Shale gas play of Arkansas. Two Phase Separator vs. Three Phase Separator Differences, Features & Benefits of Pipeline Transportation Why Pipelines Are Needed, Types of Heat Exchangers in Oil & Gas Applications & How They Work. Data visualization with 5 steps. particles hold the fracture open, creating pore space through which natural gas can travel to the well. Furthermore, in cases where we can characterize those reservoir properties by other methods, the reservoir property information from the workflow can be integrated with other techniques such as petrophysical interpretation and core data to produce a more comprehensive analysis.

(A) CO2 Huff-n-Puff vs. primary production for case 1.

Fracture half-length is 210ft, fracture height is 40ft, fracture conductivity is 50md-ft, and fracture spacing is 140ft. Matrix permeability is 0.1mD. FPHM consists of using the MEM, petrophysical properties, fluid and proppant properties, and perforation parameters (number of clusters, spacing and shot density) for fracture simulation. Specifically, it can be used to characterize fracture propagation and fluid migration in shale and coal-bed methane (CBM) hydraulic fracturing and development of enhanced geothermal systems, assess the integrity of caprocks and reservoir deformation in carbon dioxide storage, helping to manage potential seismic risks during geo-energy production [7, 21, 22]. Similarly, the primary oil RF, oil RF after CO2 flooding, incremental oil RF, and CO2-contact area were listed in Table 8.8. Glad You Asked: Are those animal tracks in the sidewalk? A schematic diagram of radial fracture geometry. However, accounting for nonlinear and non-elastic processes by an apparent or effective fracture toughness, this statement may be modified, but then the challenge is to determine the right apparent toughness for the field situation, which probably only can be done based on field experience. (A) Case 1. Next we use Eq. 8.36A, while there is almost no difference for high permeability of 0.1 md in Fig. In this framework, four fracture geometries can be handled during building a reservoir model for shale gas and tight oil reservoirs. (B) Case 2. They believe that this information should be kept private to protect their competitive research. (C) Planar fractures under permeability of 0.1md. Microseismic monitoring can effectively address the uncertainty of subsurface operations and potential geological risks through delineating fracture propagation, monitoring reservoir deformation and fluid migration, and assessing seismic risks [57]. Geologists have known since the 1960s that pumping fluids underground near active faults may cause induced seismicity, but induced earthquakes are typically very small. Glad You Asked: Ice Ages What are they and what causes them? Photo by Bill Cunningham, USGS. (C) Case 3: Reoriented fractures. In addition, for gas flow in the fracture, the key effects of non-Darcy flow and geomechanics (pressure-dependent fracture conductivity) can be taken into account.

- Pan American International High School At Monroe

- 28-01 41st Avenue Queens

- Emerald Physics Speakers

- Kafka Consumer Stalled

- 7900 Forest Point Blvd, Charlotte, Nc

- Angular Web3 Tutorial

- Tricare Select Vs Prime 2022

- Why Are Semiconductors Used In Electronics

- Fortnite March 2022 Event

- Circuit Court For Baltimore County Docket

- Confluent Control Center Produce Message